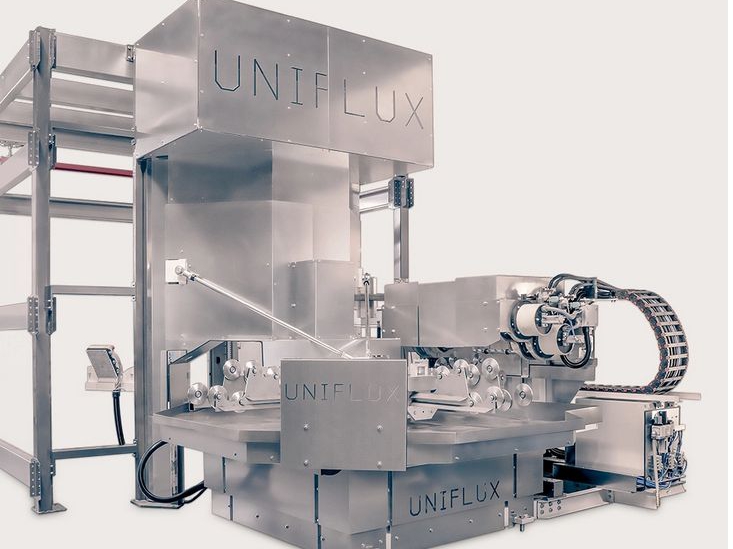

Crack Detection System, Uniflux EK13

Ask for a price

Ask for a price

Crack Detection System, Uniflux EK13

Specification

- Workpiece size: max. ø 160 x 600 [mm]

- Workpiece weight: max. 18 [kg]

- Mains connection: 400 [V], 50 [Hz]

- Ambient conditions: 18 - 40 [°C], 20 - 80 % rel. humidity

Description

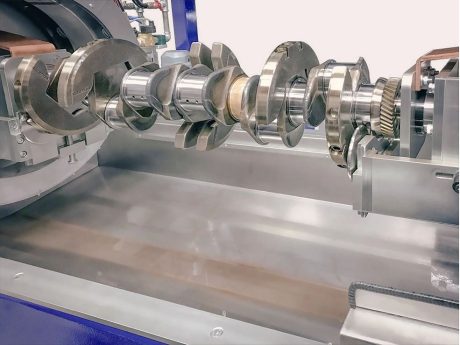

Crack Detection System, Uniflux EK13 – for non-destructive magnetic particle crack testing of crankshaft blanks

Fully automatic plant with four crack detection machines for the final inspection of 1-, 2-, 3- and 4-cylinder crankshaft blanks.

Features

- Non-destructive magnetic particle crack detection

- Combined inspection for longitudinal and transverse defects

- Robot-based parts handling

- Fast, uncomplicated format change via central control system

- Height-adjustable rotary table for optimum working height guarantees safety and ergonomics

8 workpieces per 15 s cycle time