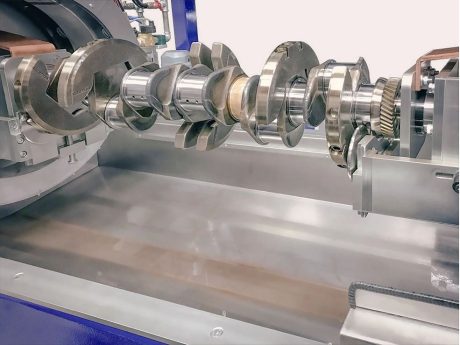

Crack Test Bench, UF 1100 SPE / UF 1100 UNOFLUX SPE

Ask for a price

Ask for a price

Crack Test Bench, UF 1100 SPE / UF 1100 UNOFLUX SPE

Specification

- Workpiece length: max. 1600 [mm]

- Mains connection: 3x400[V]

- Compressed air: 5 [bar]

- Coils: 400/500 [mm]

Description

Crack Test Bench, UF 1100 SPE / UF 1100 UNOFLUX SPE – for magnetic particle testing in accordance with EN ISO 9934 and ASTME 1444-94a.

Features

The Uniflux UF 1100 – 1600 SPE crack detection systems enable both individual and combined testing of longitudinal and transverse magnetization.

With the Uniflux UF 1100 – 1600 Unoflux SPE crack detection systems, longitudinal and transverse magnetization is only possible in separate and consecutive work steps.

Possible magnetization methods of the crack detection machine:

- Current flow: Display of longitudinal cracks

- Auxiliary flooding: display of longitudinal cracks

- Coil magnetization: display of transverse cracks

- Design of the crack detection system

Uniflux UF 1100 – 1600 SPE:

- Separate high-current generator for feeding the two magnetizing circuits

- Pneumatic clamping device in the left clamping pole

- Right clamping pole can be moved and locked by hand

- Two phase-shifted alternating currents generate a rotating magnetic field

- Mobile high-current coil D = 400 mm or 500 mm

Uniflux UF 1100 – 1600 Unoflux SPE:

- separate high-current generator for feeding the two magnetizing circuits

- Pneumatic clamping device in the left clamping pole

- right clamping pole can be moved and locked by hand

- High-current changeover switch with two functional positions:

- Workpiece clamped = current or auxiliary flow possible

- Workpiece unclamped = field or induction flow possible

- Mobile high-current coil D = 400 mm or 500 mm